Trends

Kitchen ventilation – is yours up to par?

Chefs and business owners need to know several important things about kitchen ventilation to ensure that their kitchen is safe, healthy, and comfortable for both employees and customers.

KEY INSIGHTS

- Kitchen ventilation is essential for removing smoke, heat, steam, and odors from the kitchen.

- Ventilation systems should be designed holistically across the entire premises

- Chefs should ensure that the exhaust hood, filters, and ductwork are cleaned and inspected regularly.

Chefs and business owners need to know several important things about kitchen ventilation to ensure that their kitchen is safe, healthy, and comfortable for both employees and customers.

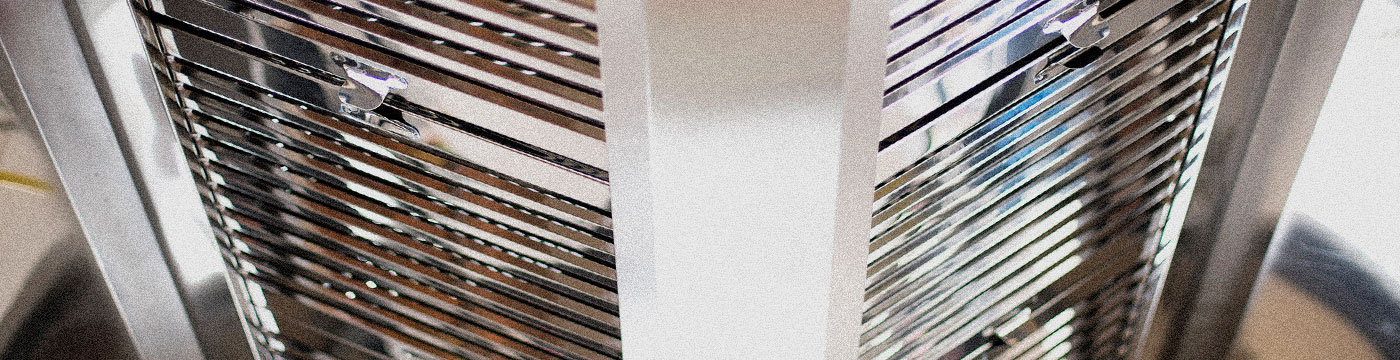

An efficiently functioning ventilation system in your kitchen is essential for removing smoke, heat, steam, and odors from the kitchen. It also helps to reduce the risk of fire, prevent the build-up of grease and other contaminants, and maintain good air quality.

There are specific regulations and codes that chefs must follow regarding kitchen ventilation, including requirements for the type of ventilation system needed, the amount of air flow required, and the location of exhaust fans and vents.

An effective ventilation system will reduce contaminants such as harmful gases and also assist by keeping the kitchen area as cool as possible. A further benefit is the removal of odours from food, cooking oils and cleaning products.

Regular maintenance of the exhaust system is critical to ensure proper functioning, avoid fire hazards, and reduce energy costs. Chefs should ensure that the exhaust hood, filters, and ductwork are cleaned and inspected regularly.

Here are some key things a chef or business owner should know about kitchen ventilation:

• Exhaust hoods for your cooktops and appliances capture and filter heat, smoke, fumes and unwanted air particulates and must be correctly sized for efficient operation. Typically a hood should hang 45cm over the front of the cooking appliance and 30cm over the side. Your hood systems should be cleaned regularly (at least four times a year, and more often if your menu includes high-fat food such as burgers along with your pizza and pasta). The more cooking equipment you have, and the higher the cooking temperatures, the more robust your exhaust systems need to be.

• HVAC (Heating, Ventilation, Air Conditioning and Cooling) systems across the entire premises should be designed holistically. As back of house in a foodservice premises requires more ventilation than front, the kitchen should be partially isolated from the dining area. The ideal air flow is from the front of house dining space/service area to the kitchen in back, then to outside through the exhaust hoods. You can test this by making sure that when the front door is open, outside air does not blow inside but rather flows back out. HVAC engineers follow airflow standards which set out how much air is required for each person in a designated space.

Premises with open plan kitchens or front of house cooking spaces will require specialised design to ensure effective air flow.

• Makeup air, this is fresh air drawn in to replace the air vented through exhaust hoods, has to come from a variety of sources. Typically these include a rooftop intake unit, open windows and doors and through the hood system itself (it is important this is correctly calibrated and switched off when the kitchen is not in use).

• Ducted air vents should be strategically positioned in your dining space to maintain a comfortable temperature for customers – not too hot, not too cold. As you don’t want cold air blowing directly onto customers or their meals, vents need to be placed so that the air from the HVAC system has a chance to diffuse before it reaches diners.

• Programmable thermostats and humidity sensors which adjust air flow to suit changing temperatures should be fitted where possible so that staff don’t need to manually adjust the ventilation during work hours. Consider investing in variable speed exhaust hoods which are equipped with sensors to allow them to operate at lower fan speeds where possible. While they cost more than conventional hoods, they’ll soon pay for themselves by reducing your energy bills.

• Ongoing maintenance of the whole ventilation system is very important. If you find condensation dripping onto the kitchen floor, an incorrectly calibrated exhaust hood might be the culprit. Regular professional cleaning of ventilation elements protects against the spread of bacteria like legionella, so make sure it’s part of your maintenance regime.

YOU MAY ALSO LIKE